In the realm of modern welding techniques, the utilization of Weld Roller Carriages has emerged as a transformative approach, significantly enhancing operational efficiency and precision. According to a report by the American Welding Society, the global welding equipment market is projected to reach $30 billion by 2025, driven largely by technological advancements and increased demand for automation in industrial applications. Weld Roller Carriages play a crucial role in this evolution, offering seamless movement for heavy workpieces and facilitating consistent weld quality. With the ability to support various welding processes, these carriages not only improve productivity but also reduce the strain on welders, resulting in safer working conditions. As industries continue to adopt these innovative tools, understanding their benefits becomes essential for maximizing output and ensuring high standards in welding operations.

In the realm of modern welding techniques, the utilization of Weld Roller Carriages has emerged as a transformative approach, significantly enhancing operational efficiency and precision. According to a report by the American Welding Society, the global welding equipment market is projected to reach $30 billion by 2025, driven largely by technological advancements and increased demand for automation in industrial applications. Weld Roller Carriages play a crucial role in this evolution, offering seamless movement for heavy workpieces and facilitating consistent weld quality. With the ability to support various welding processes, these carriages not only improve productivity but also reduce the strain on welders, resulting in safer working conditions. As industries continue to adopt these innovative tools, understanding their benefits becomes essential for maximizing output and ensuring high standards in welding operations.

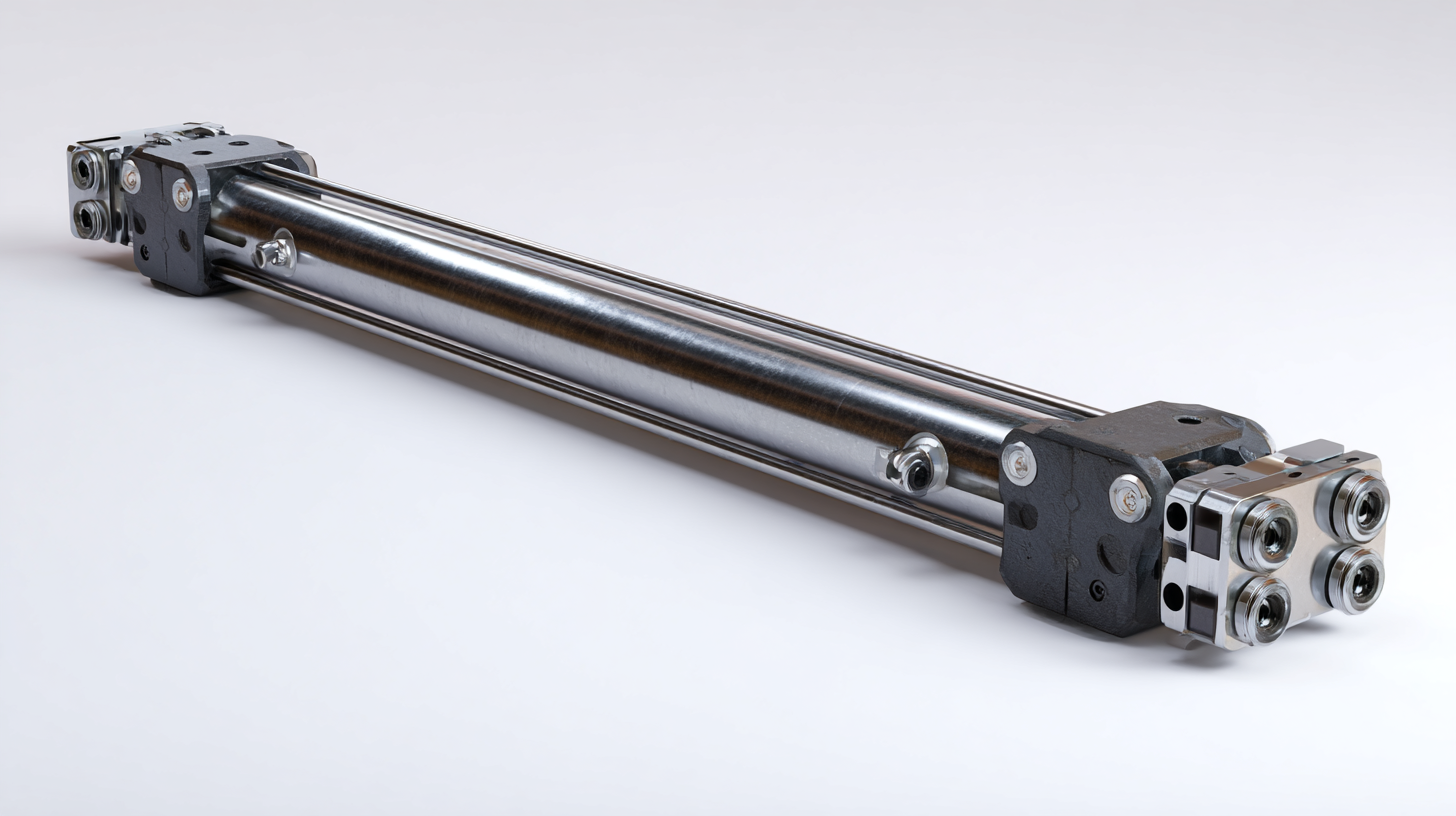

Weld roller carriages play a crucial role in enhancing welding precision, particularly in modern manufacturing environments where accuracy is paramount. By utilizing these carriages, manufacturers can ensure stable movement of the welding torch along the workpiece, minimizing human error and improving consistency in weld quality. This stability allows for intricate and precise welding patterns that are essential in sectors like aerospace, where even minor deviations can lead to significant operational challenges.

Recent advancements in welding technology have further augmented the benefits of weld roller carriages. Collaborative robotic systems, for example, are designed to work alongside human operators, significantly enhancing efficiency and precision in welding tasks. These systems integrate seamlessly with traditional setups, leading to a streamlined workflow that can adapt to the increasing demands for customized and complex welds. As manufacturers increasingly adopt these technologies, the role of weld roller carriages becomes even more vital, ensuring that the precision and reliability of the welding process continue to meet industry standards. The combination of advanced tooling and smart automation marks a transformative shift in the welding landscape, promising improved outputs and enhanced operational efficiency.

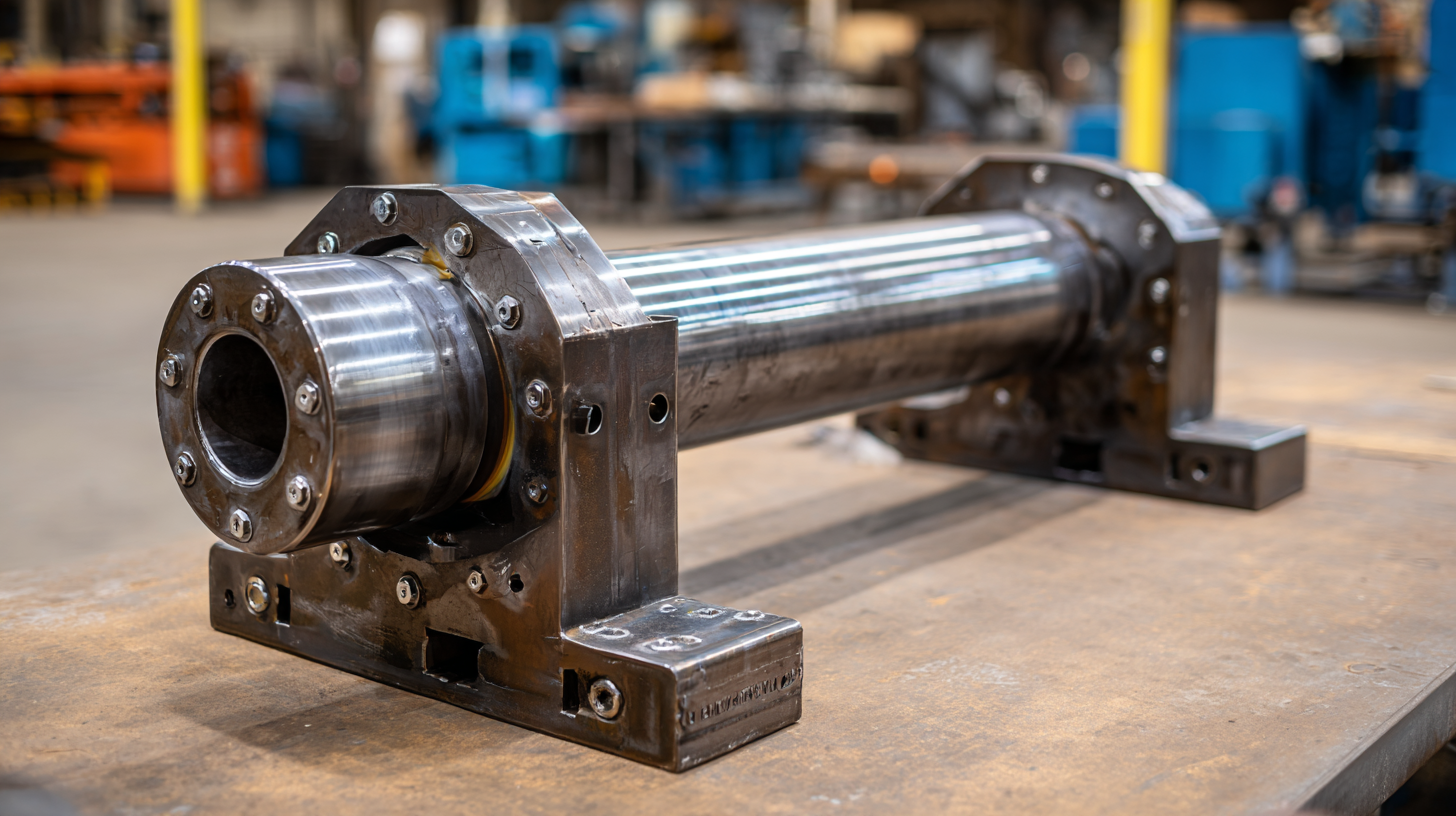

Weld roller carriages have become indispensable in modern welding applications, offering unparalleled advantages in terms of efficiency and precision. According to a report by the American Welding Society, the implementation of automated and semi-automated welding techniques has led to a 30% increase in productivity across various industries. This is largely due to the ability of weld roller carriages to support and stabilize large workpieces, reducing the need for manual handling and allowing for smoother, more consistent weld paths.

Weld roller carriages have become indispensable in modern welding applications, offering unparalleled advantages in terms of efficiency and precision. According to a report by the American Welding Society, the implementation of automated and semi-automated welding techniques has led to a 30% increase in productivity across various industries. This is largely due to the ability of weld roller carriages to support and stabilize large workpieces, reducing the need for manual handling and allowing for smoother, more consistent weld paths.

Moreover, the versatility of weld roller carriages allows them to be used in an array of applications, from shipbuilding to pipelines. Industry data shows that the use of roller carriages can reduce weld defects by up to 25%, as they ensure proper alignment and minimize the chances of misalignment during the welding process. This enhancement in quality control not only leads to significant cost savings but also increases the safety and longevity of welded structures, making them an essential investment for modern manufacturing operations.

Weld roller carriages are revolutionizing the way welding projects are executed, significantly improving workflow efficiency. According to a study by the American Welding Society, adoption of advanced welding equipment, including roller carriages, can enhance productivity by up to 30%. This increase is largely attributed to the smooth mobility these carriages provide, allowing welders to maneuver heavy components with ease, thereby reducing physical strain and increasing the speed of operations.

Additionally, a report by the National Institute of Standards and Technology highlights that integrated systems, including weld roller carriages, can minimize rework and errors by 25%. This is critical in large-scale projects where precision is paramount. With the ability to maintain a consistent distance and angle during welding, roller carriages ensure high-quality welds while reducing downtime caused by setup and adjustment processes. As welding technology continues to evolve, the incorporation of equipment like weld roller carriages appears to be a key factor in enhancing overall project efficiency.

Weld roller carriages have become an essential component in modern welding techniques, significantly impacting safety standards in various industrial applications. By enhancing stability and mobility, these carriages minimize the risk of accidents during the welding process. When used appropriately, weld roller carriages help ensure that heavy components are securely supported, reducing the likelihood of tipping or falling, which can lead to severe injuries. This increased stability not only protects welders but also improves the quality of the weld by maintaining consistent torch alignment.

Tips for using weld roller carriages effectively include ensuring that the load is evenly distributed on the carriage to prevent tipping. Additionally, always check that the wheels and bearings are in good condition to facilitate smooth movement. Regular maintenance of the weld roller carriage can prevent equipment failure, which is crucial for maintaining safety standards in the workplace. Moreover, proper training for all users on how to operate and position the carriages can further enhance safety and efficiency in welding operations.

Adopting weld roller carriages also promotes a more organized work environment. By allowing for better arrangement of equipment and materials, these carriages help reduce clutter, making it easier for welders to navigate and complete their tasks without hazards. Implementing these practices not only safeguards workers but also contributes to the overall productivity of welding operations.

| Benefit Dimension | Description | Safety Impact |

|---|---|---|

| Efficient Material Handling | Weld roller carriages streamline the process of moving heavy materials and components into position for welding. | Reduces risk of strain injuries by minimizing manual lifting. |

| Enhanced Precision | Roller carriages allow for stable and precise placement of components, which improves the accuracy of welds. | Decreases the likelihood of welding defects, enhancing overall safety in operations. |

| Increased Productivity | Using carriages minimizes downtime by speeding up the setup and positioning processes. | Higher productivity leads to safer environments by reducing rushed and careless work practices. |

| Versatility in Application | Carriages can be adjusted for various sizes and types of welding projects, accommodating diverse tasks. | Promotes safe working conditions by allowing adaptability to different equipment and environments. |

| Reduced Equipment Wear | The use of roller carriages minimizes direct contact and friction, prolonging the life of welding equipment. | Lower replacement rates enhance safety by ensuring equipment is more reliable and less prone to malfunction. |

When comparing weld roller carriages to traditional welding techniques, several key differences stand out, impacting efficiency and effectiveness. Traditional welding often relies on static positioning, which can lead to varying weld quality due to the welder's inability to maintain consistent angles and movement. In contrast, weld roller carriages provide a dynamic and adjustable platform that allows welders to work with greater precision and flexibility. This adaptability not only enhances the quality of the welds but also reduces the time spent on repositioning and aligning heavy materials.

Moreover, the ergonomic benefits of weld roller carriages cannot be overlooked. Traditional methods often require welders to adopt uncomfortable postures for extended periods, contributing to fatigue and potential injuries. Weld roller carriages, however, facilitate easier maneuverability and accessibility, promoting a more comfortable working environment. This ergonomic advantage leads to increased productivity, as welders can focus on their tasks without the distractions of discomfort or strain, ultimately resulting in a higher quality of work over longer periods.