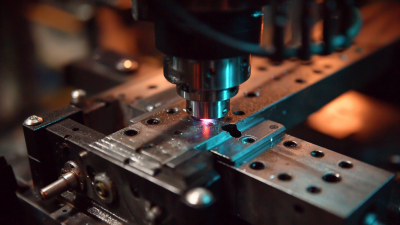

In the rapidly evolving landscape of modern manufacturing, the integration of technology has become paramount in enhancing operational efficiency and productivity. One of the pivotal advancements in this realm is the introduction of the Auto Cutting Machine. This innovative tool revolutionizes traditional cutting processes by streamlining workflows, minimizing material wastage, and ensuring precision in production. As industries strive to meet the demands of speed and accuracy, the Auto Cutting Machine stands out as a game-changer, facilitating not only faster turnaround times but also the ability to produce intricate designs that were previously unachievable with manual methods. In this blog, we will explore the significant impacts of the Auto Cutting Machine on manufacturing efficiency, providing insights and tips on how businesses can leverage this technology to stay competitive in today's fast-paced market.

The role of auto cutting machines in modern manufacturing processes cannot be overstated, particularly when it comes to minimizing material waste. These machines utilize precision technology to execute cutting tasks with unparalleled accuracy, significantly reducing excess materials generated during production. By optimizing cutting patterns and ensuring every cut is necessary, manufacturers can maximize material utilization, leading not only to cost savings but also contributing to more sustainable practices within the industry.

As the manufacturing sector increasingly prioritizes sustainability, the integration of automated cutting solutions becomes essential. These machines offer the capability to adapt cutting strategies based on the specific properties of materials, taking into account their grain, thickness, and flexibility. This level of customization further minimizes waste and enhances efficiency. Additionally, as the global market for plasma cutting machines is projected to expand, it reflects a growing recognition of the importance of technology in fostering an eco-friendly and economically viable manufacturing landscape.

The advancements in auto cutting technology significantly enhance manufacturing efficiency by optimizing production speed and accuracy. As industries face growing pressure to reduce costs and increase output, integrating automated cutting machines has become crucial. Research indicates that automating cutting processes can reduce production time by up to 30%, allowing manufacturers to meet rising consumer demands swiftly. Additionally, the precision of these machines minimizes material waste, which not only cuts costs but also promotes sustainable practices in manufacturing.

The integration of AI-driven technologies within auto cutting machines further amplifies these benefits. A recent study highlighted that businesses leveraging deep learning and machine learning techniques in supply chain management saw a 15% improvement in overall efficiency. This is particularly relevant in modern manufacturing, where synchronization between raw material supply and production schedules is vital. As companies continue to embrace automation and smart technologies, the combination of auto cutting machines and AI will likely define the future landscape of manufacturing efficiency, fostering rapid transformation across various sectors.

Auto cutting machines are transforming modern manufacturing across various industries by enhancing efficiency and precision. Case studies reveal significant advancements; for instance, in the apparel industry, a leading manufacturer reported a 30% reduction in fabric waste after adopting an automatic cutting solution. This not only streamlined their production process but also contributed to sustainability efforts, aligning with the growing demand for eco-friendly practices in manufacturing.

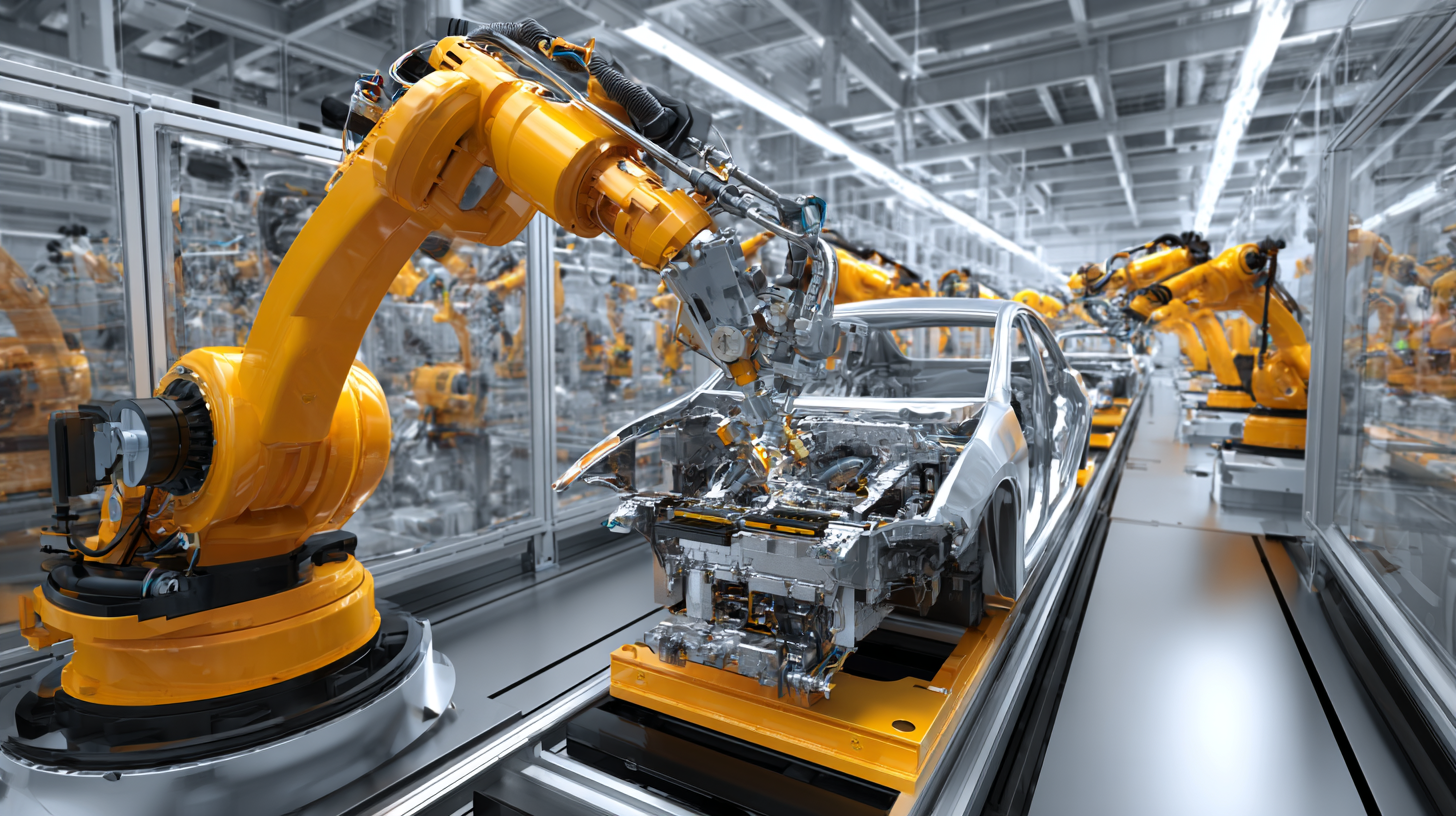

In the furniture industry, companies have noted that integrating auto cutting technology has resulted in a staggering 40% increase in processing speed. This efficiency allows for higher order fulfillment rates and improves overall profitability. Furthermore, an automotive parts manufacturer showcased a case where the implementation of automated cutting led to a 25% decrease in labor costs while ensuring consistent quality in components.

**Tip:** When considering the adoption of auto cutting machines, focus on the specific needs of your production line. Conduct a thorough analysis of your current processes to identify bottlenecks and potential savings that automation could provide.

**Tip:** Collaborate closely with your machine supplier to ensure proper training and technical support during implementation, which can significantly enhance the benefits of the new technology.

| Industry | Implementation Year | Reduction in Material Waste (%) | Increase in Production Speed (%) | Labor Cost Savings (%) |

|---|---|---|---|---|

| Textiles | 2021 | 25 | 30 | 20 |

| Automotive | 2019 | 15 | 25 | 18 |

| Furniture | 2020 | 20 | 35 | 15 |

| Apparel | 2022 | 22 | 28 | 25 |

| Packaging | 2023 | 18 | 32 | 22 |

The integration of auto cutting machines in modern manufacturing has revolutionized the industry, particularly in terms of cost savings. These advanced machines streamline the cutting process, reducing material waste significantly. By minimizing errors typically associated with manual cutting techniques, companies can maximize the utilization of raw materials, which directly leads to substantial savings on production costs. As manufacturers embrace automation, they also benefit from faster turnaround times, allowing them to meet increasing consumer demands without inflating their budgets.

In addition to reducing material waste, auto cutting machines enhance labor efficiency. Businesses can allocate resources more effectively by replacing labor-intensive cutting processes with automated solutions. This transition not only lowers labor costs but also increases productivity, as machines can operate continuously without the need for breaks. Consequently, manufacturers can scale production quickly and respond to market dynamics with greater agility. The financial impact of these machines is, therefore, twofold: improved efficiency leads to lower operational costs while also enabling higher output levels, setting the stage for better profit margins.

The evolution of auto cutting machines has become a pivotal factor in the interplay between manufacturing efficiency and the principles of Industry 4.0. These advanced machines, which integrate automation, data exchange, and smart technology, have revolutionized traditional manufacturing processes. By enhancing precision and reducing material waste, auto cutting machines enable manufacturers to achieve higher productivity levels while maintaining the quality of their outputs. The incorporation of IoT technology allows for real-time monitoring and predictive maintenance, ensuring minimal downtime and maximizing operational efficiency.

As we gaze into the future, the influence of auto cutting machines on modern manufacturing will continue to grow in tandem with Industry 4.0 advancements. The integration of artificial intelligence and machine learning within cutting machines will likely lead to even more sophisticated and adaptable systems. Manufacturers can expect these machines to not only optimize their cutting processes but also facilitate customization at scale, responding swiftly to market demands. This shift towards smart manufacturing will further streamline workflows, promote sustainable practices, and significantly elevate the overall competitiveness of businesses in the global market.

The chart illustrates the manufacturing efficiency achieved by different cutting methods. As seen, fully automatic cutting machines offer the highest efficiency, significantly improving production processes in modern manufacturing environments.