In the rapidly evolving landscape of industrial technology, the concept of "Welding Intelligence" is emerging as a critical factor in enhancing operational efficiency and precision within the welding sector.

According to a recent report by the International Institute of Welding, the global welding equipment market is poised to reach $20 billion by 2025, driven in part by advancements in automation and data integration.

These developments not only optimize the welding process but also pave the way for innovative practices that leverage real-time data analytics and machine learning.

Expert insights from Dr. Emily Carter, a renowned authority in the field of welding technology, emphasize the importance of embracing these technological advancements.

Dr. Carter states, "The future of welding lies in our ability to harness intelligent data systems that facilitate smarter decision-making and predictive maintenance." This perspective underscores the necessity for industries to adopt a "数字+Best 类型" approach that integrates digital tools and best practices, transforming welding operations into more intelligent and sustainable processes.

Expert insights from Dr. Emily Carter, a renowned authority in the field of welding technology, emphasize the importance of embracing these technological advancements.

Dr. Carter states, "The future of welding lies in our ability to harness intelligent data systems that facilitate smarter decision-making and predictive maintenance." This perspective underscores the necessity for industries to adopt a "数字+Best 类型" approach that integrates digital tools and best practices, transforming welding operations into more intelligent and sustainable processes.

As we explore the potential of Welding Intelligence, it becomes evident that the integration of advanced technology is not merely an option but a requirement for companies aiming to remain competitive in a fast-paced market.

By focusing on innovation and continuous improvement, organizations can unlock unprecedented efficiencies and quality in their welding operations, ensuring a future that is both technologically advanced and strategically sound.

The integration of artificial intelligence (AI) into welding processes marks a significant leap towards enhancing both efficiency and precision in this essential manufacturing sector. AI technologies, such as machine learning and computer vision, enable real-time data analysis, allowing for the immediate adjustment of parameters during welding operations. This responsiveness not only minimizes the likelihood of defects but also optimizes the use of resources, ultimately leading to a more sustainable and cost-effective production process.

Moreover, the role of AI extends beyond mere operational improvements. Predictive maintenance powered by AI algorithms can foresee equipment failures before they occur, reducing downtime and maintenance costs. Additionally, AI-driven simulations can aid in training welders, providing them with a virtual environment to practice and perfect their techniques. As the industry evolves, embracing these advanced technologies will not only unlock the potential for increased productivity but also set new standards for quality and innovation in welding.

The integration of IoT solutions in welding processes signifies a monumental shift towards enhancing operational efficiency and precision in the manufacturing sector. By utilizing connected devices, manufacturers can monitor welding parameters in real-time, ensuring optimal performance and immediate adjustments if anomalies arise. According to a recent industry report, companies that adopted IoT solutions in their manufacturing processes reported a 30% increase in operational efficiency and a 25% reduction in material waste, significantly contributing to sustainability efforts.

Moreover, as the automotive industry accelerates its transition towards automation and digitalization, embracing IoT technologies is not merely an option; it has become a necessity. With traditional production methods leading to excessive energy consumption, incorporating smart welding solutions enables manufacturers to reduce their carbon footprint. A study shows that introducing automation technologies can decrease energy usage by up to 40%, aligning production practices with ESG goals.

Tips: To maximize the benefits of IoT in welding, companies should prioritize data interoperability across machines and invest in training for their workforce to harness the full potential of these advancements. By doing so, manufacturers can not only enhance their welding processes but also pave the way for a more sustainable future.

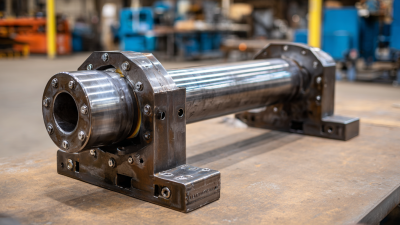

In the rapidly evolving field of welding, robotics and automation are playing a pivotal role in shaping the future of welding techniques. The advent of advanced robotic welding systems enhances manufacturing operations by improving precision and efficiency, while simultaneously addressing labor shortages in the industry. With the integration of digital twin technology, companies can simulate and optimize their welding processes, ensuring higher quality outcomes and reduced manufacturing errors. This innovation not only accelerates production but also boosts workplace safety, marking a significant leap toward intelligent manufacturing.

**Tips:** When considering robotic automation for welding, evaluate your specific operational needs and potential return on investment. Investing in employee training on these advanced technologies can also enhance productivity and improve welding outcomes.

In shipbuilding, recent partnerships between academic institutions and industry leaders are paving the way for enhanced welding processes. By exploring automation, stakeholders aim to improve the quality and efficiency of shipyard operations, crucial for meeting the demands of modern maritime projects. The focus on automation and advanced materials in welding is also indicative of broader trends influencing various industrial sectors, including underwater welding, where maintaining infrastructure integrity remains paramount.

**Tips:** Stay abreast of the latest developments in welding technologies to ensure your operations align with industry best practices. Collaborating with research institutions can provide valuable insights and foster innovation in your welding processes.

| Technology | Description | Benefits | Application |

|---|---|---|---|

| Robotic Welding Systems | Automated systems using robots for welding tasks. | Increased precision, reduced labor costs, and enhanced safety. | Manufacturing of automotive parts. |

| Laser Welding Technology | Utilizes focused laser beams to melt and join materials. | High speed, minimal distortion, and excellent control. | Electronics and aerospace components. |

| Artificial Intelligence in Welding | AI algorithms optimize welding parameters in real-time. | Enhanced quality, reduced defects, and adaptive learning. | Heavy industry and pipeline construction. |

| 3D Printing for Welding | Integrates 3D printing technology with welding processes. | Custom parts creation and reduced material waste. | Aerospace prototyping and repair. |

The global metal manufacturing equipment market is projected to reach a value of $63 billion in 2024, with expectations to grow to $64.6 billion by 2025 and reach $82.8 billion by 2032, maintaining a compound annual growth rate of 3.6%. This growth trend emphasizes the need for predictive maintenance strategies, especially within welding operations, to enhance productivity and minimize downtime. By leveraging data analytics, manufacturers can identify potential failures before they occur, thus optimizing maintenance schedules and extending the lifespan of sensitive welding equipment.

Implementing advanced technologies like real-time data monitoring and analytics can transform traditional welding operations. For instance, turning to smart welding robots can facilitate various applications ranging from rebar mesh welding to truss welding, supporting the manufacturing industry's shift toward automation and increased efficiency. Moreover, integrating 5G technology in these operations opens up possibilities for “lights-out” factories, where welding robots can perform tasks autonomously, further pushing the boundaries of productivity.

**Tips:** Utilize cloud-based platforms for ETL processing of welding logs to ensure seamless data integration and communication. Regularly train staff on new technologies to maximize the benefits of automation in welding operations. Consider predictive maintenance software that leverages historical data to enhance future operational reliability.

Welding practices are undergoing a significant transformation with the introduction of innovative materials and advanced technologies. For instance, companies are adopting techniques like automated tungsten inert gas welding, which has demonstrated enhanced efficiency and precision in challenging environments, such as mountainous construction sites. This particular method was effectively utilized in the recent construction of a pipeline, showcasing how specialized welding solutions can meet the demands of modern engineering projects.

Tips for optimizing your welding operations include focusing on training personnel in advanced techniques and investing in the latest welding equipment. Furthermore, considering innovative materials that offer better durability and performance can lead to more sustainable practices in welding.

Embracing these advancements not only improves the quality of work but also paves the way for a more intelligent and connected approach to welding. By integrating cutting-edge technology, companies can enhance productivity and ensure safer work environments, ultimately leading to a brighter future in engineering construction.